The

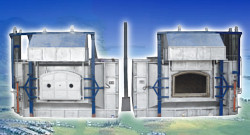

Aluminum Rod Continuous Casting and Rolling Line Equipment is composed of the

below equipment:Aluminum Melting Furnace (vertical fast energy saving furnace)+(online

degassing and filter system)+ Holding furnace(twin-chamber furnace)+(Permanent magnet

stirrer)+casting machine+shear+(induction heater)+rolling mill+rod quenching device+ rod

wire coiler (twin-coiler)+(aluminum dross processing machine)

Continuous casting machine:

Belt continuous casting machine consists of crystallizing wheel, driving device, press roll

device, steel belt greasing device, guide bridge, steel belt tensioner, external cooling inject,

steel belt, etc.

The melt aluminum flows from the holding furnace through the launder to the pouring groove,

the floating head of the plug controls the flow of the al. liquid, the liquid is poured into the cavity

formed by the crystallizing wheel and the sealed belt. The whole pouring groove can be moved

up and down driving by the power of motor. Worm gear reducer and screw pair. The section

of crystallizing wheel is M type, and it is driven by the motor. The crystallizing wheel is equipped

with an inner cooling device, which could spray cooling water onto the inner surface of the wheel

with a water pressure of 0.35 Mpa. The inner cooling water can be divided into 6 sections; the

flow could be controlled by the cut off valve. The external cooling device spray the cooling water

onto the steel belt, so as to cool the al. liquid wont flow out. The guide wheel is used to adjust

or change the direction of the steel belt and change the length of the cavity. The tension of the

steel belt can be changed through the tensioner, so as to keep a certain tension. In order to

strip the al. ingot, the continuous casting machine is equipped with steel belt greasing device.

Because the whole process is not interrupted long ingot can be gained.

Continuous rolling mill:

The continuous rolling mill consists of 15 rolling stands of three rollers typeY.The nominal

dia. is 255mm. there are 7 upper driving device for even number rolling stands and 8 lower

driving device for odd number rolling stands, they are arranged alternately.The type of

the hole is "circuit-arc triangle circuit". The main DC motor transmits the power through the

coupler and the main shaft under the 12th rolling stand of driving gearbox.The transmission ratio between two neighboring stands is 1:1.25; there is safe tooth like coupling in the junction

of the gear box and rolling stands.When it is overloaded, the safe pin will be cut to avoid the accident. In the front and the back of the rolling stands there are inlet and outlet guide device.

The rolling guide device is used in the odd number rolling stands, and the sliding guide device is

used in the even number rolling stands. Small roller of every rolling stands can be adjusted by

shims of the different thickness; the range can be 0.1 to 1.00mm. The adjustment of the hole every rolling stands is taken out by a certain plug gauge. The seam can be 0.866mm,the tolerance

is ±0.10mm.

The thin-oil lubricating system is used to lubricating the driving gearbox and bearings

中文版

中文版  Français

Français English

English  Español

Español العربية

العربية